Industry: Medical

Product: Airbrush® Liposculpture

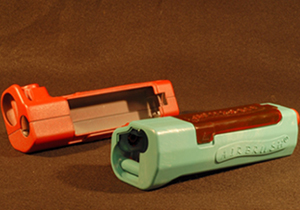

The Challenge: A busy cosmetic surgery practice in New York needed

a highly functional housing for its newly patented liposuction device,

the Airbrush® Liposculptor. In addition to efficiently storing the

existing hardware, the model had to be two colors and withstand sterilization

temperatures up to 220 degrees. The Airbrush® Liposculptor also required

an ergonomic design to facilitate one-handed, continuous adjustment

of rate and stroke, to reduce both the surgeon's physical exertion

as well as operating time.

The Challenge: A busy cosmetic surgery practice in New York needed

a highly functional housing for its newly patented liposuction device,

the Airbrush® Liposculptor. In addition to efficiently storing the

existing hardware, the model had to be two colors and withstand sterilization

temperatures up to 220 degrees. The Airbrush® Liposculptor also required

an ergonomic design to facilitate one-handed, continuous adjustment

of rate and stroke, to reduce both the surgeon's physical exertion

as well as operating time.

The ART Solution: ART began with 3-D CAD files from Cadability Inc. to create a prototype for form and fit testing in the field. From this design, we produced urethane models for several months of clinical trials. Tweaking the design after each trial, we developed five iterations until the client felt the device had been perfected. The final step: creating the tooling used to mass produce the device.

The Results: Initially conceived as a product for a single practice, the cosmetic surgeon and inventor was so pleased with the results that he’s now marketing and selling the Airbrush® Liposculptor to other practices. With each iteration of the device,

ART prototypes saved the client nearly $40,000 in tooling costs, creating enormous

value along with a superior product.