It’s All in the Details: ART and PolyJet™ Printing

For

prototypes with remarkably precise feature details and smooth surface

finishes, ART offers an alternative rapid prototyping choice: Polyjet™

Printing.

For

prototypes with remarkably precise feature details and smooth surface

finishes, ART offers an alternative rapid prototyping choice: Polyjet™

Printing.

Polyjet™ printing allows tremendous precision, with layers up to seven times

finer than standard stereolithography models. Prototypes can be built from seven

different resins making ART’s 3-D printer extremely versatile. The fine layer

resolution and the material options make the process well-suited for building

amorphic shapes, tiny figurines, rubber-like parts, and injection molded-like

models.

Whatever your vision, from game board action heroes, to laser scanned fossils, to toothbrushes and shaving razors, ART’s Polyjet™ printers have successfully served the needs of a wide variety of industries. And, just like its SL counterparts, completed Polyjet models will be accurate and finished to meet your desired specifications.

Polyjet™ Capability:

- Produces ultra fine details with .0006 inch (16 microns) horizontal layers

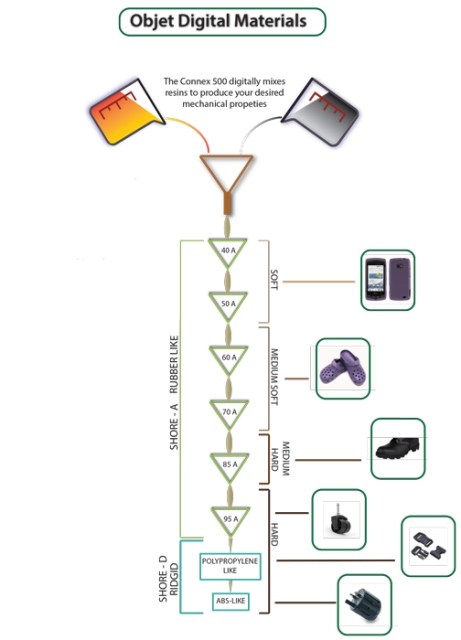

- Currently able to print seven different resins, including flexible, Shore A materials that work well for:

- Gaskets

- Grommets

- Strain-reliefs

- Button pads

- Rigid Materials

- Vero White plus

- Vero Clear

- ABS-Like

- Digital PP-Like

- Flexible Materials

- Tango Black plus

- Tango plus

- Digital 40A

- Digital 50A

- Digital 60A

- Digital 70A

- Digital 85A

- Digital 95A

- Digital Materials Data Sheet

- PolyJet Materials Data Sheet

- Objet Digital Materials

- 1) Polyjet™ printing technology works by jetting a photopolymer material in ultra-thin layers (0.0006 inch) onto a build tray, layer by layer.

- 2) Each layer is cured by UV light immediately after it is jetted.

- 3) The high-resolution 0.0006 inch layers ensure smooth, accurate and highly detailed models.