High-Performance Materials: The Specifics

ART uses only the finest quality resins, urethanes and other build materials for each and every project. Superior performance resins, such as DSM Somos, ensure our craftsmen and engineers have the most versatile tools available to produce outstanding, high-functioning parts for our clients.

We use DSM Somos resins exclusively for our Stereolithography parts, including the following resins:

- 9120 (Off white and durable)

- NeXt LV Grey (Nylon/ABS-like)

- 11122 WaterShed XS (Highly clear, colorless)

- 12120 ProtoTherm (High Heat)

- Rigids

- Vero White plus

- Vero Clear

- ABS-Like

- Digital PP-Like

- Flexibles

- Tango Black plus

- Tango plus

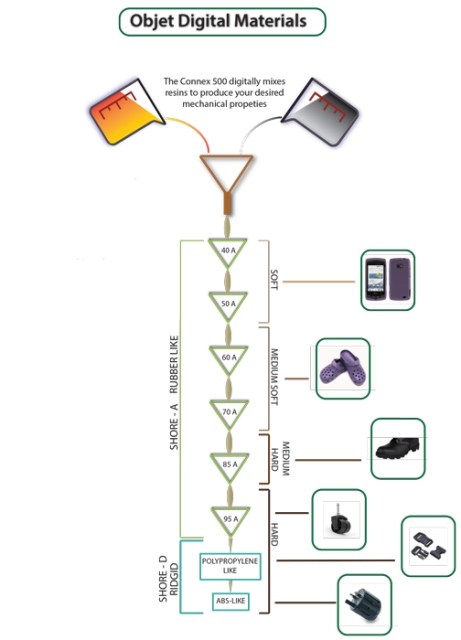

- Digital 40A

- Digital 50A

- Digital 60A

- Digital 70A

- Digital 85A

- Digital 95A

- Digital Materials Data Sheet

- PolyJet Materials Data Sheet

- Objet Digital Materials

- ABSplus (40% stronger than ABS)

- ABSi (Translucent)

- ABS-M30 (25-70% stronger than ABS)

- ABS-m30i (Biocompatible and can be gamma or EtO sterilized)

- ABS-ESD7 (Thermoplastic with static dissipative properties)

- PC (Strong)

- PC-ABS (Strong and heat resistan)

- PC-ISO (Biocompatible and can be gamma or EtO sterilized)

- PPSF/PPSU (Greatest heat and chemical resistance)

- ULTEM 9085 (Flame retardant and high strength-to-weight ratio)

- Rigids

- 283-10 (Shore D-83, Ultra Clear, great for thin wall parts, can be tinted)

- 284-05 (Shore D-80, Propylene-like, great for production)

- WC 792 (Shore D-84, Water clear, impact strength, weatherability, heat, UV light and oxidation resistance )

- TP 4004 (Shore D-70, TPO-like, tough, impact resistant)

- TP 4005 (Shore D-70, TPO-like, tough, impact resistant, stiffer than 4004)

- TP 4006 (Shore D-80, High Impact, high heat resistent)

- TP 4007 (Shore D-80, Semi-transparent, tough and impact resistant)

- VA 274 (Shore D-83, Water clear, low viscosity)

- TC 812 (Shore D-65, Light weight filled, low viscosity)

- TC 854 (Shore D-84, ABS-like, Good general purpose material)

- TC 872 (Shore D-70, High heat resistance, high impact)

- TC 878 (Shore D-78, Clear, heat resistance, high impact)

- TC 879 (Shore D-78, Clear, heat resistance, high impact)

- TC 885FR Shore D-78, (High impact)

- TC 895 (Shore D-84, High heat resistance)

- TC 896 (Shore D-82, High heat resistance)

- PT 8902 (Shore D-85, Tough, heat resistance)

- Flexibles

- F 32 (Shore A-32, Tensile and tear strengths)

- F 42 (Shore A-42, Tensile strength and elongation)

- F 60 (Shore A-60, Shock absorbent)

- F 62 (Shore A-60, Fire retardant)

- F 70 (Shore A-70)

- F 90 (Shore A-90, Exceptional abrasion and impact resistant)

- WC 565 (Shore A-65, Water clear)

- WC 575 (Shore A-70, Water clear)

- RTV 3040 (Shore A-38, Rubber for reproducing intricate detail)

- ST 1060 (Shore A-60, Multi purpose)

- ST 1085 (Shore A-85, High tear strength and toughness)

- ST 3040 (Shore A-40, Strong, resilient elastomer)

- ST 1060 (Shore A-60, Strong, resilient elastomer)

- TC 460 (Shore A-60, Multi purpose)